THE FOOD INDUSTRY IS STRONGLY

IMPACTED BY MSDs

occupational diseases in the food industry are linked to MSDs

millions euros of contribution costs incurred

working days lost per year

The proof in these two very affected sectors

dairy products sector

The 6 essential pieces of equipments

in the food industry

After several years of working with our clients in the food industry, we have been able to define 6 "flagship" and, above all, essential products to integrate to improve their workstations.

our happy clients speak best about it

the device. At end of the day it is much less tiring as we are no longer required to use a step ladder, which is an increase in safety in the workshop.

our selection in detail

ZOOM IN ON

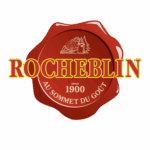

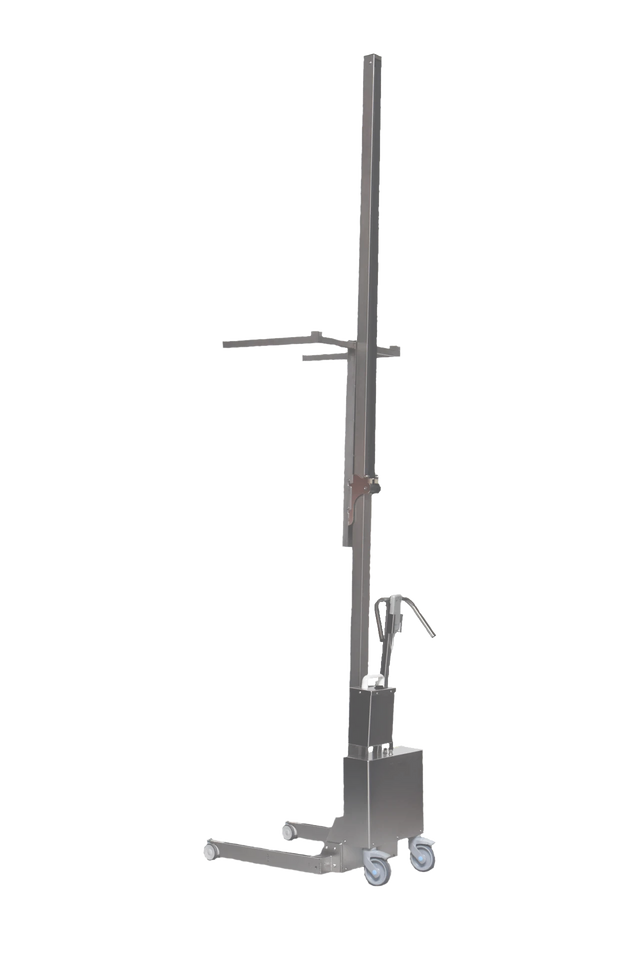

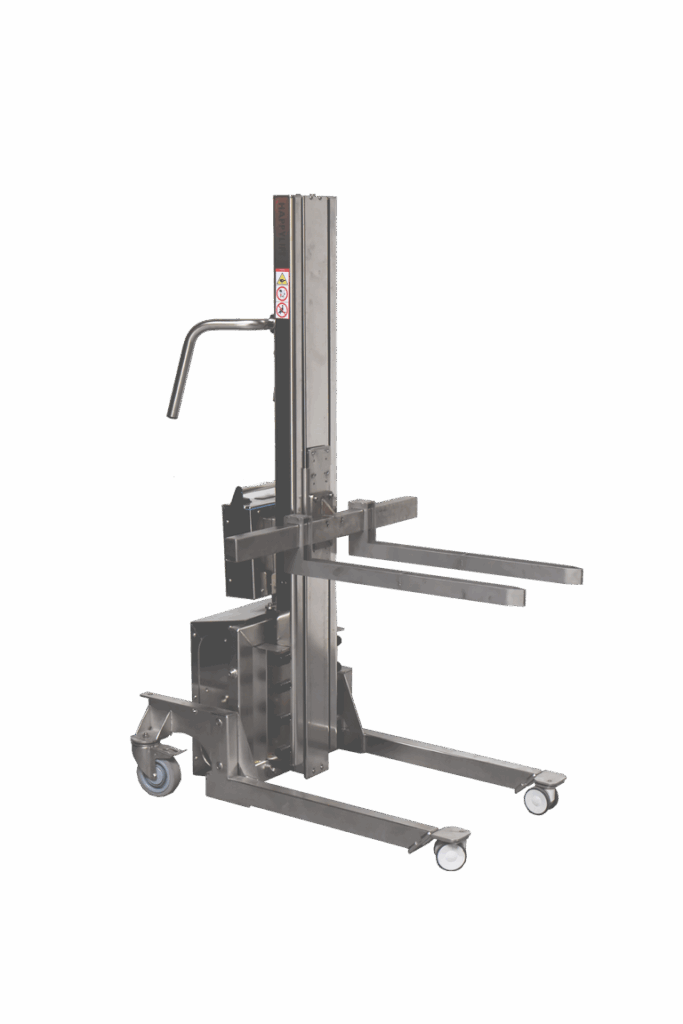

STAINLESS STEEL MINI LIFTER

HAPPYLIFT100

Our HAPPYLIFT100 range of handling lifters is designed to handle loads of up to 100 kg. Equipped with a remote control and extremely manoeuvrable, these trolleys offer several mast heights and customisable bases, making it easy to lift and safely handle various types of loads.

They are

particularly suitable for demanding

environments, guaranteeing reliability and

compliance with hygiene standards.

AISI304 Stainless Steel Construction

Capacities from 100 to 300 kg

From 0 to 3 meters

TOOL 1

Stainless Steel Tray Accessory Ref: OPTLIFT1001

Single stainless steel platform

TOOL 2

Forks for crate dollies

TOOL 3

Accessory Ref: OPTLIF1020

Double spur reels

TOOL 4

2-in-1 Tool:

V-cradle & spur

TOOL 5

Happylift Ref: LIFT100ML1

Roller Tray Accessory Ref: OPTLIF1010

Roller Tray

TOOL 6

Happylift Ref: LIFT100HL2

Fork Accessory Ref: PSM

Gripping Fork

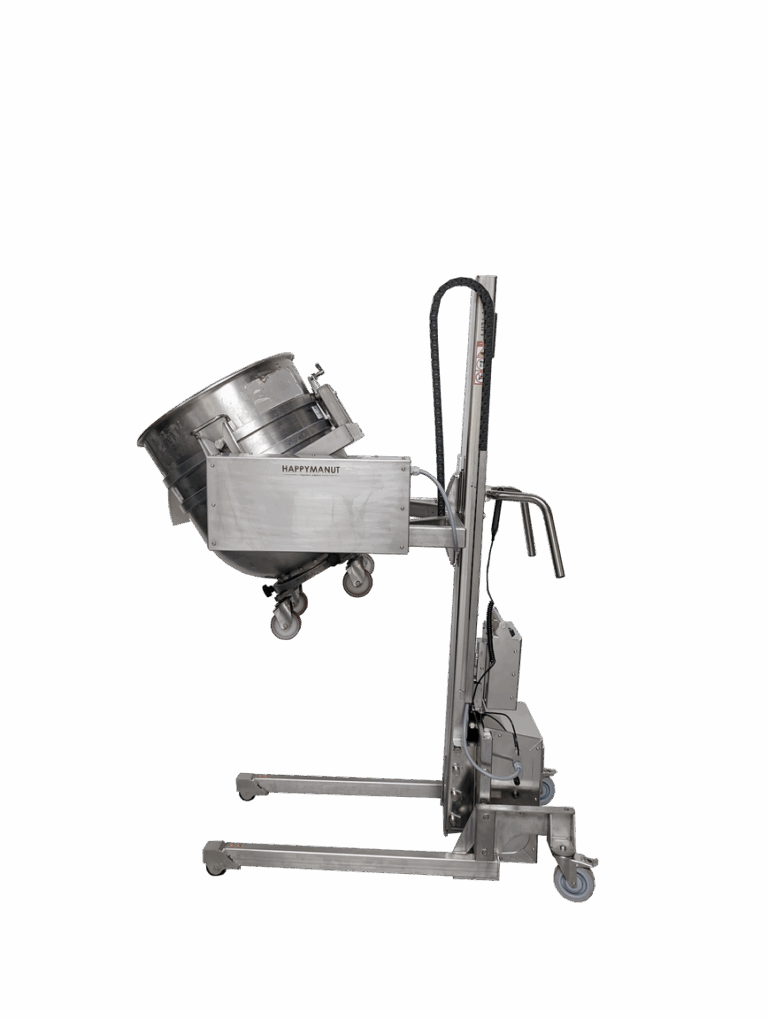

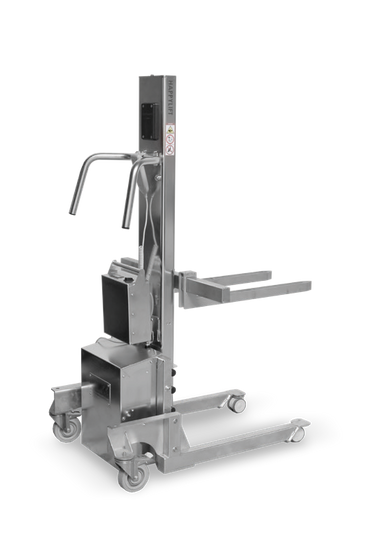

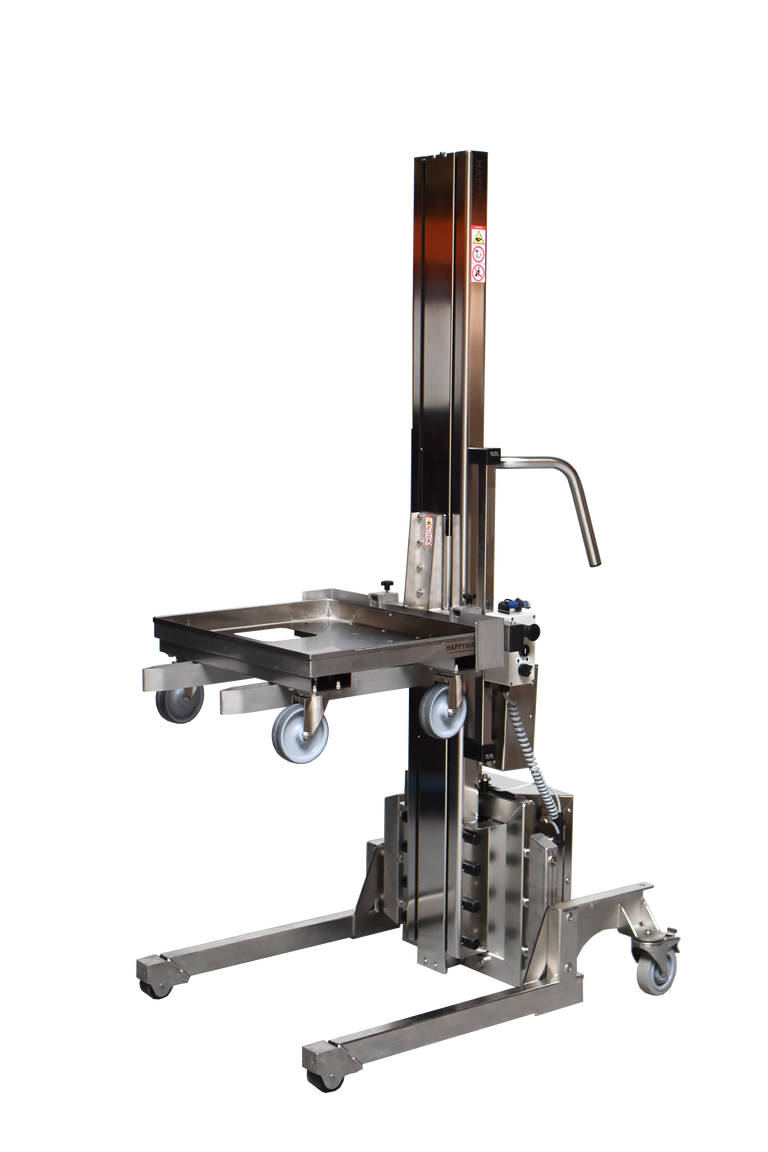

ZOOM IN ON

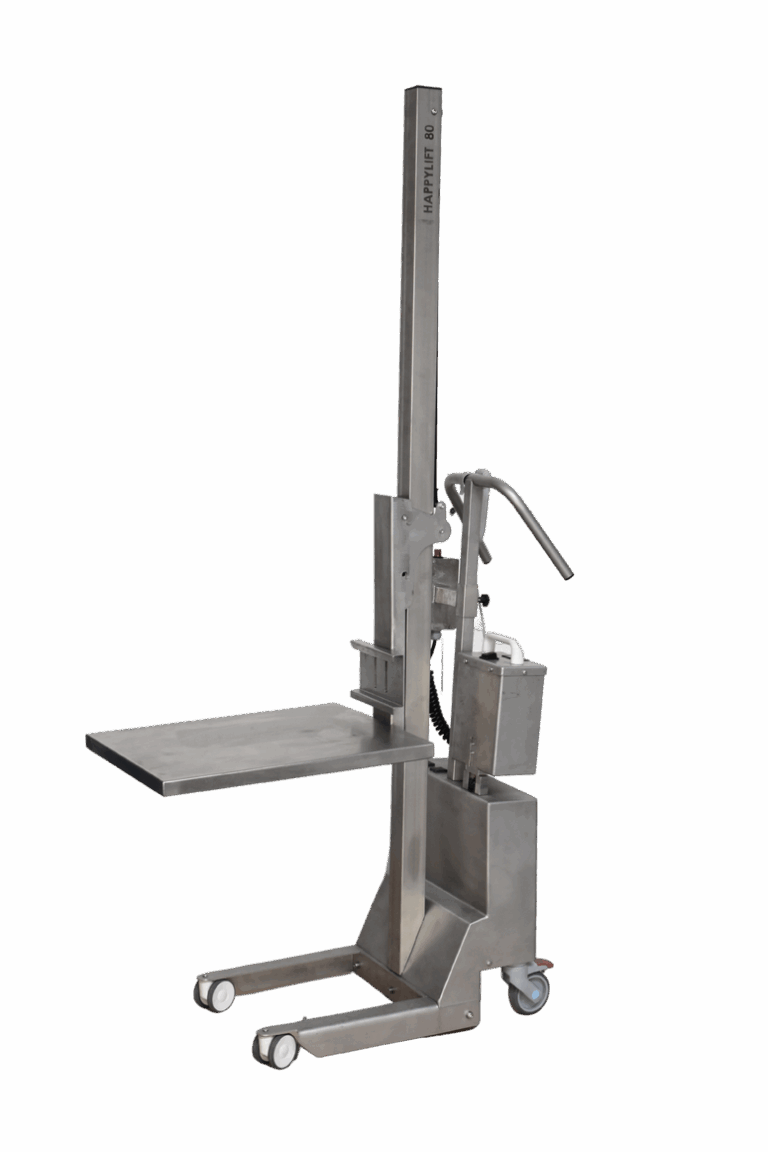

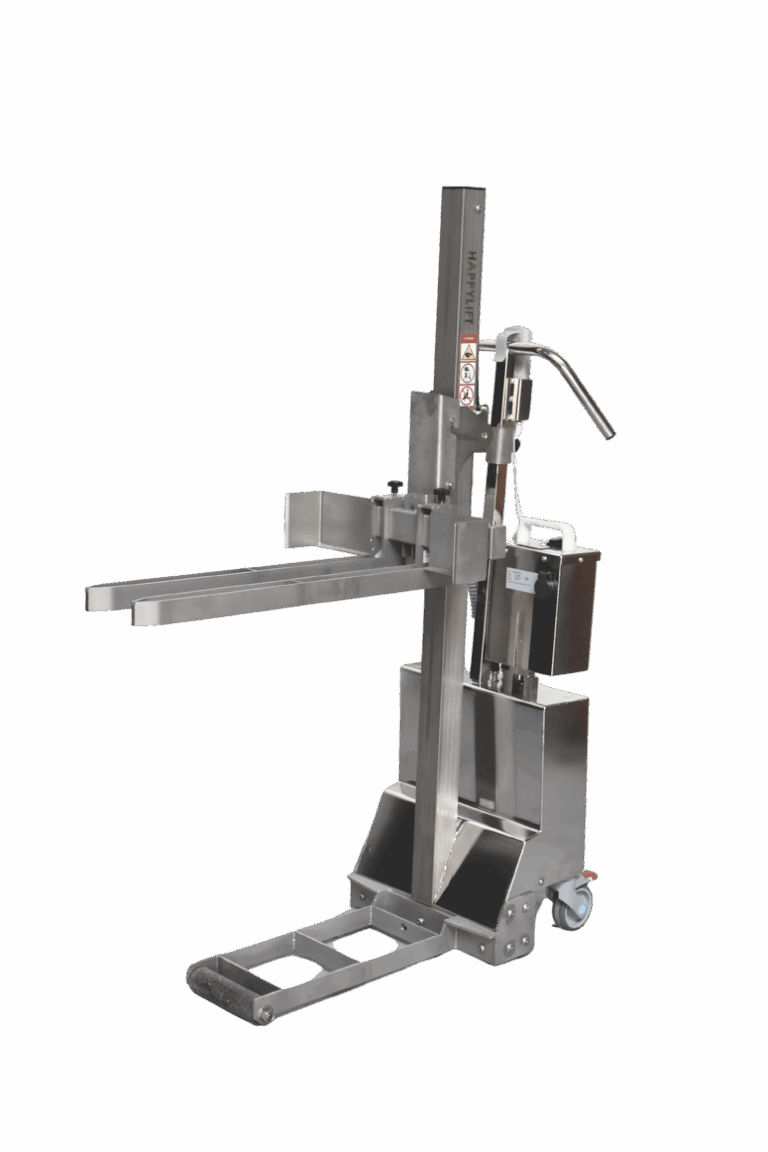

STAINLESS STEEL MINI LIFTER

HAPPYLIFT200 & 300

Our HAPPYLIFT200 and 300 handling trucks are designed to safely lift and handle loads up to 200 kg and 300 kg. Equipped with a remote control, they offer precise control and adapt to various needs thanks to their customizable mast heights and bases.

Reliable and

compliant with hygiene standards, they

are ideal for facilitating the daily handling

of your loads.

AISI304 Stainless Steel Construction

From 200 to 300 kg

From 0 to 3 meters

TOOL 1

Happylift Ref: LIFT300ML3

Tank Gripper Accessory Ref: PSM

Tank Gripper

TOOL 2

Coil Turner Accessory Ref: OPTLIFT2326

Coil handler

TOOL 3

Accessory Ref: OPTLIFT2338

Stainless Steel Roller Base Fork Accessory Ref: PSM

Fork for stainless steel rolling base

Packaging: the fork accessory for stainless steel rolling bases levels a stack of stainless steel GN containers automatically thanks to its constant level senser.

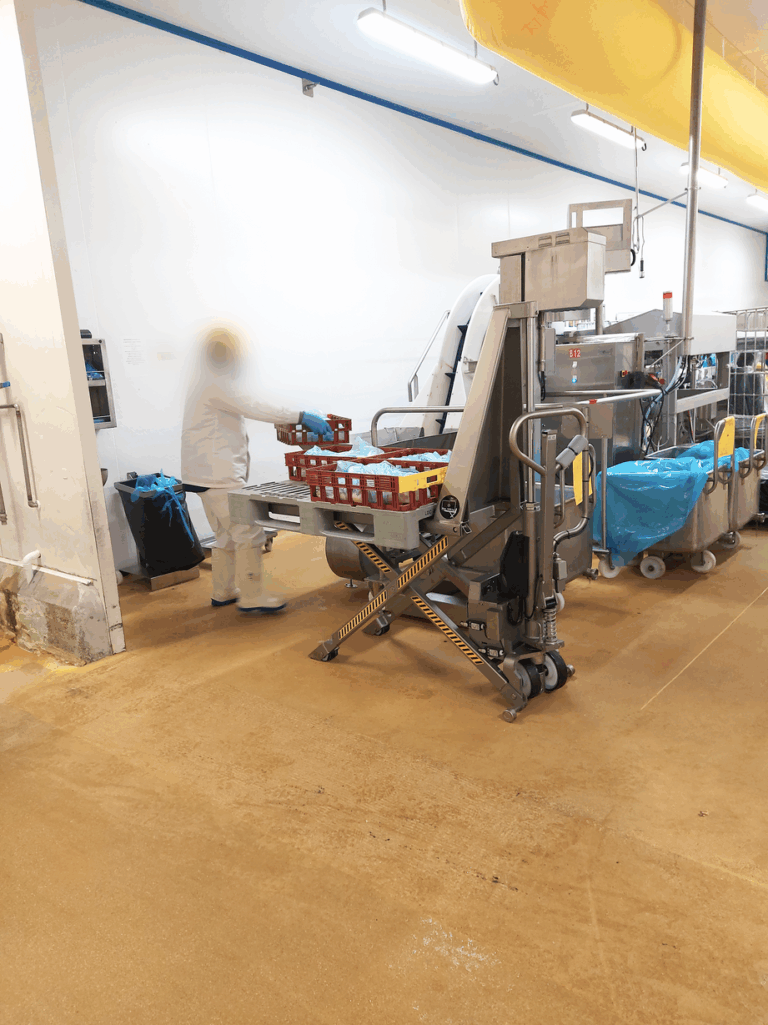

TOOL 4

Happylift Ref: LIFT200SL2

Constant Level Accessory Ref: OPTLIFT2338

Crate Fork Accessory Ref: PSM

Adjustable Forks

In production: the rack fork attachment makes leveling an entire stack easy. The operator no longer needs to lift or bend down.

ZOOM IN ON

STAINLESS STEEL HIGH

LIFT PALLET TRUCK

HAPPYPAL

We offer a range of high lift manual pallet trucks to electric pallet trucks to facilitate the handling of loads.

Made from stainless steel, these sturdy pallet trucks are resistant to moisture and chemicals, ensuring long-lasting efficiency over the years.

AISI304 Stainless Steel Construction

Lift height up to 800 mm

Hygienic (easily cleanable with plenty of water)

EXAMPLE 1

Electric Stainless Steel HL Pallet Truck Ref: TP0102002

Electric Stainless Steel HL Pallet Truck with Constant Level Ref: TP0102003

Electric high lift

pallet truckHAPPYPALOAD

EXAMPLE 2

Motorized Electric High-Lift Pallet Truck HAPPYPALGOLEV

Electric leveling and movement of pallets, facilitating traction and lifting of the load to reduce operator effort.

ZOOM IN ON

1.3T STAINLESS STEEL

ELECTRIC PALLET TRUCK

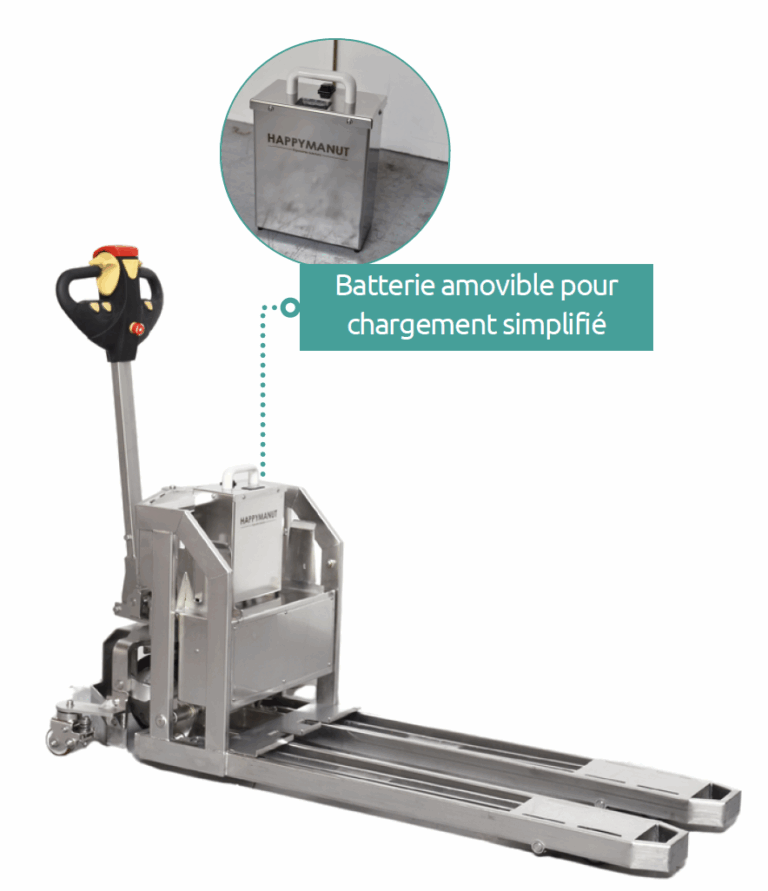

HAPPYPALGO

The HAPPYPALGO 1.3T stainless steel pallet truck facilitates pallet handling by offering safety and comfort. Its motorized wheel reduces physical effort and provides smooth electric assistance. Designed for humid and cold environments, it is resistant to the demands of the food industry.

Robust, hygienic, and maneuverable, it optimizes daily logistics with ergonomics, performance, and durability.

AISI304 Stainless Steel Construction

Removable Battery

Electric Movement (motorized wheel)

EXAMPLE 1

1.3T Pallet Truck Ref: TP0101003

Handling Stacks of Cheese Crates

EXAMPLE 2

1.3T Pallet Truck Ref: TP0101003

Handling Various Pallets

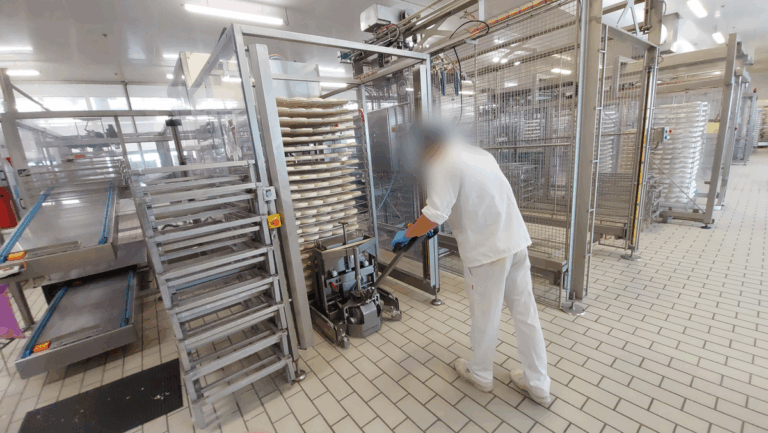

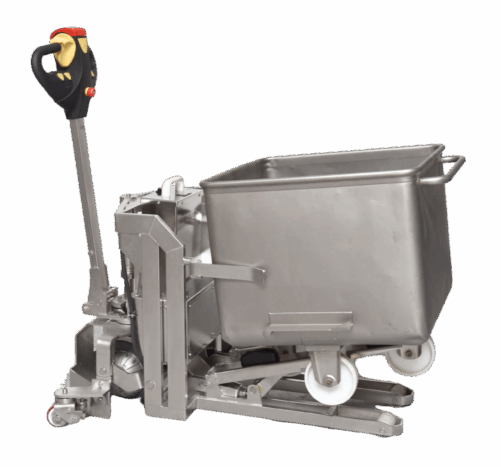

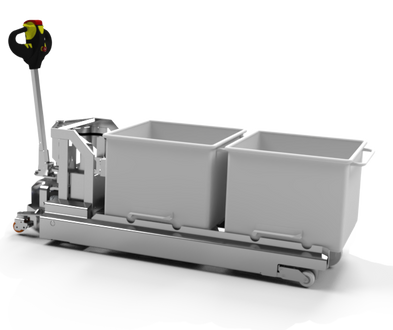

ZOOM IN ON

STAINLESS STEEL MOTORIZED TOW BARS

HAPPYTRACT

Our HAPPYTRACT stainless steel motorized tow bars facilitate the handling of Euro containers and stainless steel tanks used in the food sector. Designed for demanding environments, they allow moving up to 1200 kg safely.

With optimal maneuverability and stability.

AISI304 Stainless Steel Construction

Removable Battery

Electric Movement (motorized wheel)

EXAMPLE 1

Motorized Tow Bar for 1 Euro Container Ref: TRACT400

Motorized Tow Bar HAPPYTRACT400

1 Euro Container Model: facilitates container handling, improves ergonomics, and allows working without bending, thus reducing back pain.

EXAMPLE 2

Motorized Tow Bar for 1 Euro Container Ref: TRACT800

Motorized Tow Bar HAPPYTRACT800

2 Euro Container Model: It is now possible to pull 2 (or 3 containers: HAPPYTRACT1200) at once over long distances, with a simple and secure grip on the containers, allowing for easy traction.

ZOOM IN ON

STAINLESS STEEL TABLES

HAPPYWORK

Our range of adjustable height tables is solid, hygienic, and ideal for demanding environments such as the food industry or laboratories. It is manually height-adjustable, allowing it to be adapted to each user for optimal comfort and improved ergonomics.

Multiple dimensions are available to meet your closest expectations.

AISI304 Stainless Steel Construction

Electric or manual

Adjustable from 600 / 700 to 1000 mm

EXAMPLE 1

Electric Model: HAPPYWORKPLAN

In production: The electric height-adjustable serving trolley is ideal for working at the correct height thanks to its remote control.

EXAMPLE 2

Manual Model: HAPPYWORKTABLE

For packaging: The manual height-adjustable table is perfect for adjusting to your desired height thanks to its foldable crank.

ZOOM IN ON

STAINLESS STEEL LIFTING TABLES

HAPPYLIFTINGFIX

Our fixed electric stainless steel lifting tables are perfect for adjusting a load and providing the operator with a work environment at the appropriate height.

They are corrosion-resistant and easily cleaned, thus ensuring impeccable hygiene.

AISI304 Stainless Steel Construction

Capacity up to 10 t

Lift height up to 3 m

EXAMPLE 1

Ref.: TEF010101001

Stainless Steel Single Scissor Lifting Tables

Ideal for the food industry, they are perfectly suited for packaging lines as well as palletizing areas.

+28 options available

Mechanical Stops, photocells, rail chassis, raised chassis, roller conveyor, platform securing, inspection hatch, HD execution, limit switch, gate guardrail, guardrail, offset steel, etc.

Source of key figures: CARSAT Accident Report Year 2021

Solutions Adapted to the demands of the Food Industry

In the food industry, material handling is subject to very specific constraints: humidity, variable temperatures, strict hygiene requirements, and sustained pace. This is why we design material handling equipment for the food industry that is robust, hygienic, and perfectly adapted to your processes.

Our food-grade stainless steel solutions ensure hygienic and durable, complying with HACCP standards and facilitating daily cleaning. Whether it’s for transporting containers, raw materials, or finished products, our ergonomic systems reduce arduousness, prevent MSDs, and optimize productivity. As each environment is unique, we offer tailored support to meet the demands of food production, while preserving the health and efficiency of your teams through thoughtfully designed and adapted material handling equipment.

Custom Support for optimized ergonomics

In a sector as demanding as the food industry, every material handling solution must be hygienic, resistant, and easy to maintain. At Happymanut, we go further by integrating ergonomic considerations from the outset into our material handling equipment for the food industry.

Our experts analyze your workflows, sanitary constraints, and the repetitive movements of your operators. The result? Custom-made systems: adjustable, compact, manufactured from food-grade stainless steel, and designed for durability. They facilitate load transfer while reducing strain, and integrate seamlessly into your production lines or packaging rooms. Because well-designed handling means more comfort, fewer downtimes, and improved efficiency. Contact us for a personalized study.